ПРО НАС

Wood drying means wood hydrothermal treatment, namely removing moisture from it, as a result of which wood out of raw material transforms into industrial one that meets certain requirements set forth by various types of production and household facilities. As wood moisture content changes, its shape and volume change (decrease) and it becomes more resistant to decay.

Woodworking industry uses different types of wood drying: atmospheric, chamber, contact, drying in liquids, induction, rotary and radiation.

WHY US?

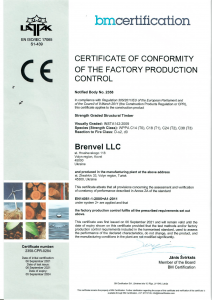

Permits

Type of drying

Brenvel LLC uses in its operations the drying chambers with fan-generated forced air circulation.

Chamber drying process runs in several stages and involves intensive blowing of wood with a stream of hot air followed by its cooling.

The chambers have conditions provided to adjust motion speed and air temperature, which allows the wood to dry quickly enough.

Depending on the season and dried materials thickness, the drying process takes from 4 to 6 days.

Our company, for the most part, dries wood in the form of lumber.

Our advantages

Our equipment ensures even drying of wood

We utilize high-throughput cameras

Highly qualified specialists and advanced equipment ensure proper stacking of timber in the drying chamber

High-quality storage of raw materials and related management

Accuracy of observing the drying regime

Professionalism of stackers and masters of drying shop

High-quality wood drying

Powerful and modern wood drying chambers

Brenvel LLC capacities allow drying both own timber and materials of other business entities on a commercial basis. We have two powerful modern wood drying chambers: two-section and three-section, which are equipped with an automatic process control system.

The benefits of chamber drying include the possibility of loading a significant volume of wood in one cycle, drying materials to a given humidity, which is practically impossible with other types of drying. In addition, moisture removal occurs evenly.

Due to chambers large areas, after drying, we have the opportunity, if necessary, to impregnate the dried materials with antiseptic agents directly in the drying chambers.

Drying equipment

Our drying chambers operate and are heated by own solid fuel boilers, which minimizes the possibility of drying interruptions.

Wood that has undergone drying has low humidity and is almost unaffected by fungi, retains its shape and size, it becomes stronger and lighter, does not crack. Dry wood is better processed and acquires a beautiful appearance after processing.

We use modern conductive and high-frequency moisture meters to determine the relative humidity of wood.

PRIORITIES

Brenvel LLC

Brenvel LLC production capacities, use of state-of-the-art equipment from national and international manufacturers, as well as educated, highly qualified employees make it possible to ensure fast and high-quality drying of wood.

Brenvel offers its customers favourable terms of cooperation

QUESTIONS?

Contact us

Telephones:

Office:

33 Zhezhkiv Street, Turiisk, Kovel District, Volyn Region, 44801, Ukraine

Business hours:

Mon-Fri: 8:30 - 17:30 | Sat-Sun: Closed